Click and move

Patented

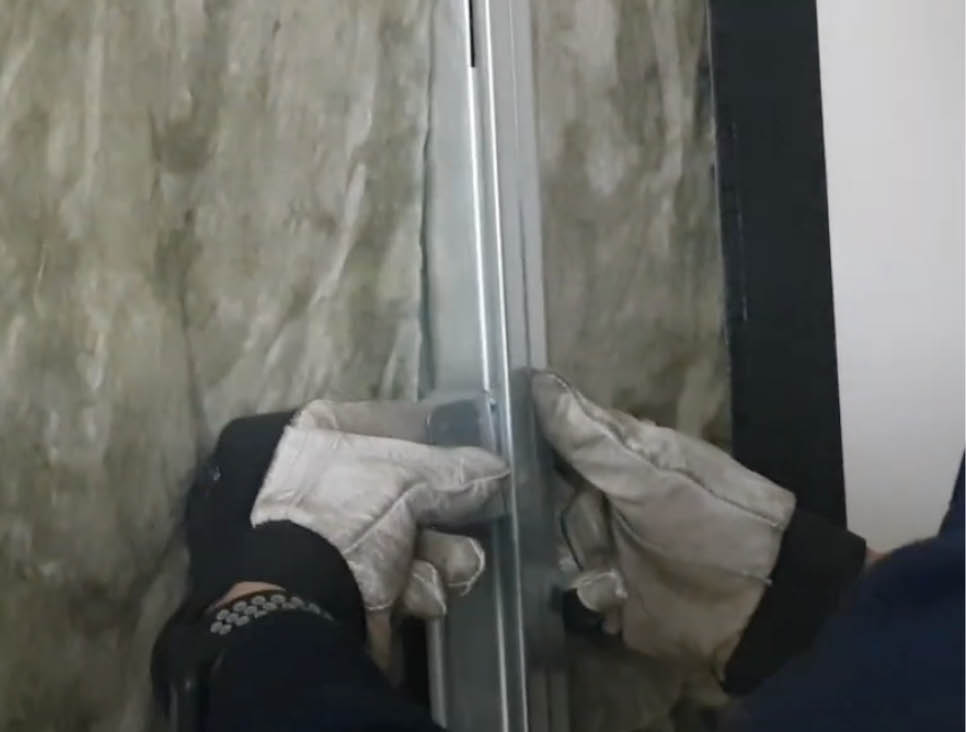

3802-03/TD1 it incorporates a new movement and PATENTED translation control system that allows the bifid extension plate to work freely in both directions. Our engineers work very hard to maximise safety, testing and verifying the ideal axial compression of the polymer before it´s leaving our factory. This process has allowed us to obtain acoustic improvements to airborne noise above 16 dBA.

Available in two thicknesses: 0,8 mm and 1,5 mm.

✓ 3802/TD1: L square in 1,5 mm thickness

STRONGER for air chambers over 10 cm.

✓ 3803/TD1: L square in 0,8 mm thickness.

Bending the square with your hands has never been so easy before! It has the advantage of bending and reducing the size of anti-vibration mount to adapt it to smaller spaces.

✓ Load range from 5 to 30 kg for both products.

The difference lies only in the thickness of the sheet metal.

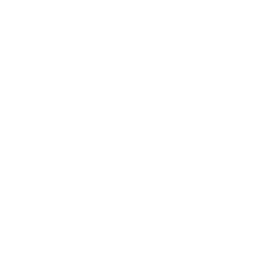

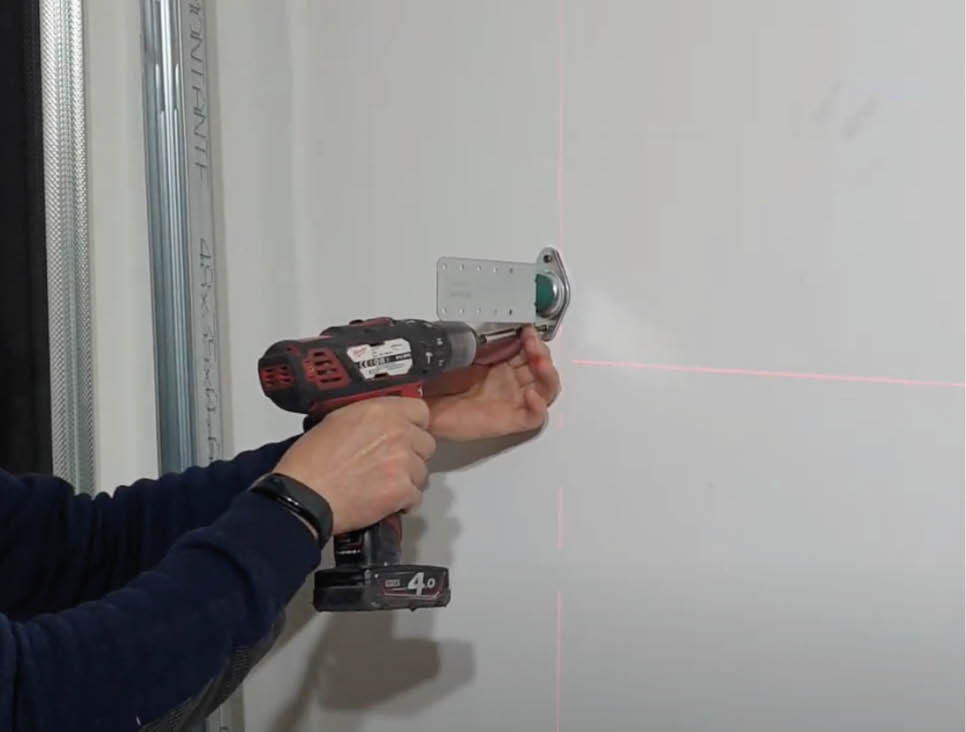

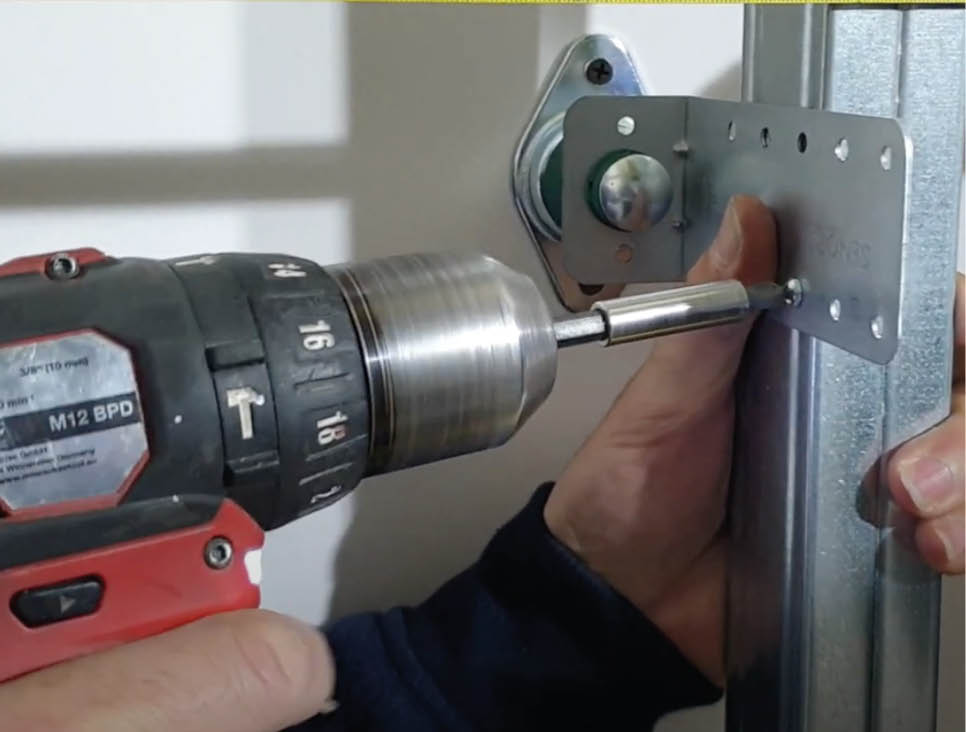

Installation video

Installation video

LATERAL ANIT-VIBRATION MOUNT DESIGNED FOR ACOUSTIC WALL INSULATIONS WITH IT´S DOUBLE FIXING ABILITY ALLOWING TO INCREASE THE SECURITY OF THE SYSTEM

Here you can download the installation manual

![]() Installation manual 3802-03/TD1

Installation manual 3802-03/TD1

![]() Product registered in the Spanish Patents and Trademarks Office

Product registered in the Spanish Patents and Trademarks Office

![]() Possibility to build wall lining systems with air chambers with several thicknesses and hold the sound absorbing material

Possibility to build wall lining systems with air chambers with several thicknesses and hold the sound absorbing material

![]() They avoid vibration transmission. The polymer works both in compression and elongation.

They avoid vibration transmission. The polymer works both in compression and elongation.

![]() Easy installation

Easy installation

![]() The two anchor points guarantee a stabler support.

The two anchor points guarantee a stabler support.

![]() It has a central shaft to ensure the system in case of fire

It has a central shaft to ensure the system in case of fire

Load Range: 5-30 kg

Resonance frequency: 7 – 15 Hz

Box format:

– SE-3802/TD1 – 50: 50 units

– SE-3802/TD1 – 16: 16 units

– SE-3803/TD1 – 50: 50 units

– SE-3803/TD1 – 16: 16 units

Test Report Nº: B2020-LACUS-IN-122-2 A

Purpose: Airborne Soundproofing Test

Standards: UNE-EN ISO 10140-1:2016 and 10140-2:2011

Laboratory: TECNALIA (Vitoria, SPAIN)

Date: 23 October 2020

Sample: CHOVA+SENOR SELF-SUPPORTING ACOUSTIC WALL LINING

Standardised Base Wall: 15 cm concrete block + plasterboards on both sides

Standardised Base Thickness and Weight: 17.5 cm and 300 kg/m²

Total Wall Lining Thickness: 19.5 cm

Sample Description: Self-supporting wall lining system comprising: SE-3802/03 TD1 dampers (SENOR) + SE-TAV-500/11A and 11R acoustic plugs (SENOR) + SE-BEC-10×100 and SE-BEC-6×100 acoustic strips (SENOR) + 48 mm channels and studs (KNAUF) + SE-MONT-BICAPA-40 decoupling strip (SENOR) + 4 cm CHOVANAPA sound-absorbing material (CHOVA) + 15 mm Plasterboard (KNAUF) + 4 mm VISCOLAM 65 acoustic membrane (CHOVA) + 12.5 mm Plasterboard (KNAUF).

Result: An improvement of 17 dB in airborne sound compared to the base wall, which has a rating of 48 dB, resulting in a total soundproofing of 65 dB.

![]() Laboratory measurement of airborne sound insulation improvement – WITH DAMPERS –

Laboratory measurement of airborne sound insulation improvement – WITH DAMPERS –

![]() Laboratory measurement of airborne sound insulation improvement – WITHOUT DAMPERS –

Laboratory measurement of airborne sound insulation improvement – WITHOUT DAMPERS –

Construction detail

With our interactive video you can ask us what you need, we will answer you as soon as possible!

ACTUAL PHOTOS

To help you

Need more help?

WE WILL BE IN TOUCH WITH YOU AS SOON AS POSSIBLE

Related products

CERTIFICATE ISO 9001

SENOR guarantees through its international certificate that we comply with quality standards, being an organization with an effective quality management system, identifying areas for improvement and taking measures to progress in them. Our goal is to provide the best service to our customers.

Designed for acoustic wall lining system

> 16 dB